Limekilns

Many Dorset villages, hamlets, private estates and farms once had their own limekilns, to produce lime for building mortar and especially for agricultural improvements. Lime producing technology was introduced to Britain by the Romans. A probable Roman limekiln was discovered in Colliton Park, Dorchester during excavations in 1938. Lime-burning is referenced in accounts of building works and repairs at Corfe Castle in the thirteenth and fourteenth centuries.

The chemical process of lime-burning (calcination or calcining) is outlined below. Calcium carbonate (limestone or chalk), heated to 900℃ or above, releases carbon dioxide (thermal decomposition) and yields around half its original mass in calcium oxide (lime or quicklime). At these high temperatures the reaction has a characteristic peachy glow (limelight). The resulting calcium oxide reacts violently (hence quicklime) with water to form hydrated (slaked) lime which is much more soluble than limestone.

CaCO3(s) → CaO(s) + CO2(g)

CaO(s) + H2O(l) → Ca(OH)2(aq)

Slaked lime, in the form of lime putty, sets by reacting with atmospheric carbon dioxide to reform calcium carbonate.

Ca(OH)2(aq) + CO2(g) → CaCO3(s) + H2O(l)

In the presence of silicate and aluminate minerals (clays), lime undergoes more complex setting reactions that do not depend on carbon dioxide and so can even occur under water, hence hydraulic lime. Similar processes are involved in the setting of modern cements and concretes.

A typical Dorset limekiln was built into a bank, often the side of an existing limestone quarry or chalk pit, with a protective wall around the top or kiln head. Construction was of local stone, with thick insulating walls. Inside was a brick-lined pot, with inverted bottle shape, tapering down towards an iron grate or grill. A major feature was a draw arch (access arch) in the front wall which included a draw-hole (eye) providing the draught to the kiln and a means of removing the burnt lime. Poking holes, above the draw-hole, allowed testing of the extent of burning and loosening of the kiln contents. Often a canopy or lime shed was attached over the draw arch and protected the lime-handling working area from the rain and wind.

Limestone and chalk were loaded, as fist-sized lumps, into the kiln pot, from the top of the bank. Alternate layers of stone and fuel (wood, gorse or coal) were loaded. Gaps between the stones allowed the even distribution of heat and the escape of carbon dioxide. As the burning proceeded the lime would crumble and collapse and be extracted through the draw-hole at the bottom. This would allow the further addition of limestone and fuel in an extended batch process which might last several days.

The major use was for agricultural purposes with lime being considered as a 'manure'. Even the limestone and chalk areas of Dorset tend to have have a thin, acidic, nutrient poor soil (e.g. clay-with-flints). Treatment with lime neutralises soil acidity, improves the soil structure and adds soluble nutrients; calcium and magnesium ions together with potassium, phosphate and suphate ions from the fuel ash (potash). The wood or gorse fuel would often be obtained from useful clearance of agricultural land.

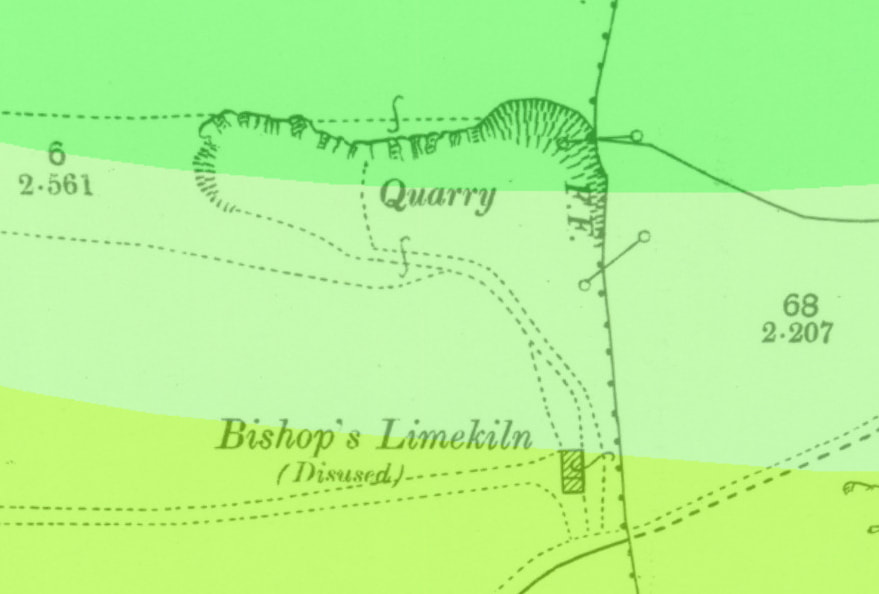

The agricultural use of lime perhaps began in the sixteenth century in Dorset, was widespread by the late eighteenth century, though fell into decline by the early twentieth century. Early ordnance survey maps, published around 1900, have many Old or Disused Limekilns marked. This decline was driven by agricultural depressions, the use of chemical fertilisers, the adoption of Portland cement for building and the switch to a few larger-scale, continuous lime kilns.

Limekilns were common in any area where limestone was quarried. Typically rubbly material that could not be used as building stone would be used for lime production. Often, beds of building stone or freestone have an overburden of more broken limestone. For example the Rubbly Beds overlying Inferior Oolite Sherborne Stone, Cornbrash overlying Forest Marble, and Purbeck beds overlying Portland Stone. The Grey Chalk Subgroup (Lower Chalk) conveniently outcrops on lower escarpments and valley sides and provided the convenient source for a large number of pits for lime-burning. It is likely that many pits in the White Chalk Subgroup (Middle and Upper Chalk) hills produced 'lime' for direct application to land, without burning.

At a few coastal locations, limestone with a naturally significant silicate and aluminate (clay) mineral content was used to produce hydraulic lime. Such hydraulic lime was produced from the Blue Lias Limestone around Lyme Regis and Charmouth and used in sea defences such as the Cobb. Dolomitic limestone bands (Cattle Ledge and Grey Ledge) in Kimmeridge Bay provided the hydraulic lime securing the Yellow Ledge Stone Band blocks used to build the old pier below the western end of Hen Cliff.

Dorset limekilns were extensively documented by Peter Stanier in the 1990s. Together, these papers provide the the most authoritative source of information:

Stanier, P. (1993) Dorset Limekilns: a first survey. Proceedings of the Dorset Natural History and Archaeological Society, 115, 33-49.

Stanier, P. (1995) More Dorset Limekilns. Proceedings of the Dorset Natural History and Archaeological Society, 117, 91-94.

Limestone and chalk were loaded, as fist-sized lumps, into the kiln pot, from the top of the bank. Alternate layers of stone and fuel (wood, gorse or coal) were loaded. Gaps between the stones allowed the even distribution of heat and the escape of carbon dioxide. As the burning proceeded the lime would crumble and collapse and be extracted through the draw-hole at the bottom. This would allow the further addition of limestone and fuel in an extended batch process which might last several days.

The major use was for agricultural purposes with lime being considered as a 'manure'. Even the limestone and chalk areas of Dorset tend to have have a thin, acidic, nutrient poor soil (e.g. clay-with-flints). Treatment with lime neutralises soil acidity, improves the soil structure and adds soluble nutrients; calcium and magnesium ions together with potassium, phosphate and suphate ions from the fuel ash (potash). The wood or gorse fuel would often be obtained from useful clearance of agricultural land.

The agricultural use of lime perhaps began in the sixteenth century in Dorset, was widespread by the late eighteenth century, though fell into decline by the early twentieth century. Early ordnance survey maps, published around 1900, have many Old or Disused Limekilns marked. This decline was driven by agricultural depressions, the use of chemical fertilisers, the adoption of Portland cement for building and the switch to a few larger-scale, continuous lime kilns.

Limekilns were common in any area where limestone was quarried. Typically rubbly material that could not be used as building stone would be used for lime production. Often, beds of building stone or freestone have an overburden of more broken limestone. For example the Rubbly Beds overlying Inferior Oolite Sherborne Stone, Cornbrash overlying Forest Marble, and Purbeck beds overlying Portland Stone. The Grey Chalk Subgroup (Lower Chalk) conveniently outcrops on lower escarpments and valley sides and provided the convenient source for a large number of pits for lime-burning. It is likely that many pits in the White Chalk Subgroup (Middle and Upper Chalk) hills produced 'lime' for direct application to land, without burning.

At a few coastal locations, limestone with a naturally significant silicate and aluminate (clay) mineral content was used to produce hydraulic lime. Such hydraulic lime was produced from the Blue Lias Limestone around Lyme Regis and Charmouth and used in sea defences such as the Cobb. Dolomitic limestone bands (Cattle Ledge and Grey Ledge) in Kimmeridge Bay provided the hydraulic lime securing the Yellow Ledge Stone Band blocks used to build the old pier below the western end of Hen Cliff.

Dorset limekilns were extensively documented by Peter Stanier in the 1990s. Together, these papers provide the the most authoritative source of information:

Stanier, P. (1993) Dorset Limekilns: a first survey. Proceedings of the Dorset Natural History and Archaeological Society, 115, 33-49.

Stanier, P. (1995) More Dorset Limekilns. Proceedings of the Dorset Natural History and Archaeological Society, 117, 91-94.

Further background information on Pre-industrial Limekilns has been published by Historic England.

Information on the use of lime for building conservation, restoration and new builds is available from the Dorset Centre for Rural Skills.

© Geoffrey Rowland, 2018